Treatment Plant Installation Case Study

Subject Property and Drainage Network

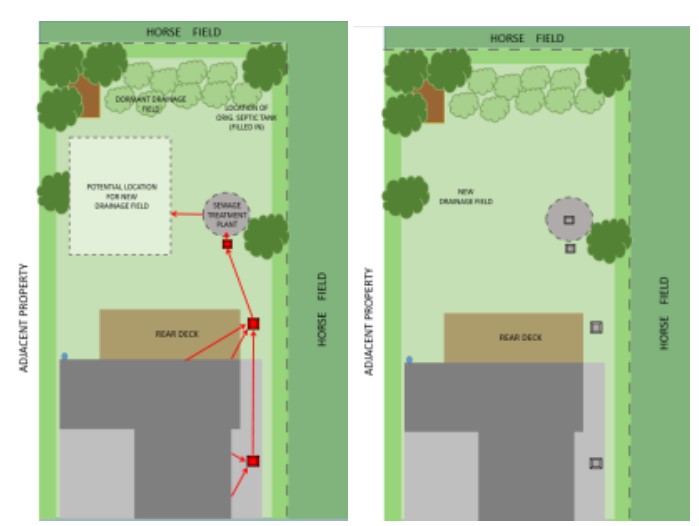

The subject property had reportedly had problems with the constant high levels of effluent building up in the current septic tank. So much so that the tank has required constant emptying and at considerable cost.

The Septic tank was populated via two manholes (MH1 & MH2). Both are situated on the side of the property and had positive natural flow.

Ecodrain Solutions proposed the installation of a Sewage Treatment Plant that will be able to treat the waste and provide acceptable effluent that will run to a new drainage field.

Sewage Treatment Plant

Acting as an independent waste water treatment system, a domestic sewage treatment plant would be installed into the rear of the property. It is a self-contained plant that is designed to receive all of the waste water from the dwelling and promote the growth of Aerobic Micro-organisms which degrade the receiving waste water producing a treated effluent suitable for discharge to a natural water courses or drainage fields.

The specific plant we proposed is an industry leader that we were confident would treat the waste efficiently and at very low operational cost.

Some facts about the proposed Sewage Treatment Plant:

∙ Extremely clean effluent – up to 98.9% pollutant reduction.

∙ Fully adjustable to suit the number of people using it.

∙ Low electricity consumption for the air pump – from only £25/year.

∙ Much lower maintenance costs than Non-Electric Treatment systems.

∙ Odourless – complete aerobic digestion throughout the sewage treatment plant. ∙ One piece tank construction – not sectional – no leaking seals.

∙ Recycles its own waste products resulting in less sludge to remove.

∙ No Primary Settlement Tank – No Primary Tank Odour.

∙ 10 year tank warranty- no metalwork to corrode inside or outside the tank.

∙ Accepted by the Environment Agency for discharge without the need for a permit

The Installation Process

The installation of the plant was a methodical procedure that required working from the side to the rear of the house (current manholes), the side patio and then into the garden.

The most important thing about the operation of any drainage network is the positive natural flow of the system. Plainly put, water runs down. The subject property’s current network had the building’s foul waste make its way to and through Manhole 1 & 2, then ultimately through a drainage pipe to the septic tank. Manhole 1 is 535mm deep and Manhole 2 is 830mm deep. These depths provide enough slope for waste to travel. However, the sewage treatment plant Ecodrain Solutions proposed to install had invert inlet depth options of 200mm, 500mm and 950mm. Due to the topography of the subject property we recommended the 500mm inlet depth so the plant outlet is high enough for the new drainage field to work effectively. This recommendation meant that we needed to change the depths of the current Manholes whilst presenting positive flow leading to the sewage treatment plant.

Additional to the Installation of the foul water network, we requested that the homeowner liaise with the owner of the adjacent Horse Field and install temporary access to Ecodrain Solutions for delivery and use of machinery (Digger & Dumper Truck), materials and the delivery of the sewage treatment plant itself.

Installation Process:

∙ Pulled up and store patio slabs

∙ Excavated and removed old manholes and installed new manholes to correct height. ∙ Installed a mini manhole prior to the proposed plant (for future access and inspection).

∙ Excavated (approx. 2m deep & wide) and prepared base for plant installation. ∙ Excavated trench for drainage pipes from plant to mini chamber.

∙ Excavated and installed a mini chamber (for future access and inspection)

∙ Excavated a trench for drainage pipes from the mini chamber to drainage field.

∙ Excavated and installed a drainage field.

∙ Installed an electrical line from the subjects property to the plant (for air pump operation).

∙ Secured and attached the plant by cuffing using cement and stone.

∙ Connected and tested the system.

∙ Backfilled all excavations and left the site level.